April 27, 2015

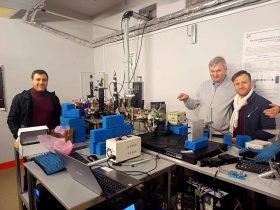

The experimental results on generation of optical vortices using the glass based microstructure gratings produced at DELTA Microfabrication station have been discussed during the visit of Dr. Vahagn Gharibyan (DESY, Germany) to the CANDLE SRI. The optical vortices were generated by illuminating the fabricated gratings with a Gaussian beam of a He-Ne laser.

An optical vortex is a beam of light the phase of which varies in a corkscrew manner along the propagation direction. Very often referred to as a “twisted light”, such a beam carries an orbital angular momentum and experiences zero intensity at its center due to the cancellations of the twisting along the propagation axis. On a surface perpendicular to the propagation direction, an optical vortex looks like a ring of light, with a dark hole in the center. Due to a number of interesting properties, the optical vortices are under extensive study for applications in the fields of optical tweezers, STED microscopy, optical coronagraphs, etc.

The method used for fabrication of the grating microstructures in DELTA Microfabrication station is based on computer-generated fork holograms, which represent simulated patterns corresponding to a phase interference of a plane wave with a beam carrying an orbital angular momentum. The simulated grating patterns are reproduced on a glass by direct laser writing using the second harmonic (512 nm) of the AREAL high-intensity ultrafast laser and the high-precision, PC-controlled microfabrication station.

Taking the advantage of material low thermal heating reduction which is due to ultrafast laser processing, the fine micro-gratings on glass with various patterns corresponding to different topological charges of optical vortices were fabricated.

The possibility of fabricating precise patterns on glass at the DELTA laboratory will allow to generate efficient optical vortices of high-intensity photon beams which significantly extend the range of potential applications of these optical elements.