Project description:

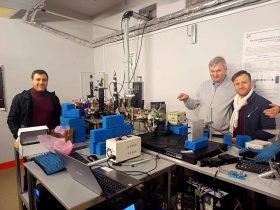

The ultrafast laser micro-processing station at CANDLE SRI is an integration of a high-performance workstation for sample 3D positioning/motion and a highly stable, femtosecond laser system. Combined with a sample motion and pulse-parameter control units and software, the station represents an entire lab on an optical table for diverse scientific and R&D applications. A range of laser and scanning parameters can be varied to select among different types of the material treatment: selective material removal, laser-induced modification of chemical, electronic and optical properties, ablation-deposition, two-photon polymerization, etc. Depending on the material and the treatment type, micron and sub-micron feature sizes can be achieved in hole-drilling, cutting, surface patterning and in-volume writing in transparent materials.

Particular fields of expertise of the Group include:

- High-precision patterning of soft and inorganic surfaces, micromachining of microelectronics and optoelectronics parts;

- Surface and 3D (in-volume) direct laser writing of complex patterns in glasses and other transparent materials for optical and photonics applications;

- Two-photon polymerization and precision fabrication of hybrid organic/inorganic polymer structures for micro-optics and optoelectronics applications.